With digital film being what it is, data concerns have become big business (not that they weren’t already). We don’t need to tell our readers how many TBs are used in the average feature or short film. Particularly, when you consider how much data the new 4K & 6K cameras chew through and the difficulty in archiving it all. The quickest and stablest way to archive huge files is by using LTO (Linear Tape-Open ) tapes.

It’s vital to get all of your work archived once you’ve finished on a project, not only for your own library of work, but most producers will want a copy of the archive too. Or if you work in corporate videos, often businesses will request a copy for many reasons.

In its current form, LTO-6 Ultrium has a 30-year life and is able to store 6.25 TBs (compressed) per cartridge, with transfer speeds of up to 1.4 TBs/hr.

However labelling all of those tapes, so that you know exactly what’s on them, can become a bit of a nightmare.

An example of which is Australia’s DDP Studios post production house, whose Technical Innovation Manager, Simon Alberry had the job of looking for a more efficient way to manage the large volume of LTO tapes he and his team needed for their work on feature films, including Alex Proyas’ Gods of Egypt, Backtrack and Josh Lawson’s Little Death.

After an exhaustive search, Alberry finally contacted Fujifilm Australia to find out if they had any products or ideas for clear cine-labelling.

Alberry explained, “Our clients have asked for their LTO archives to be clearly labeled on the shelf so they can grab exactly what they need when they need it immediately. They also would prefer to know what’s on each tape without first having to sort through large documents or trawl through old databases.”

In order to make the previous single strip, cardboard insert labelling system more efficient, Alberry discussed his needs with Marc Van Agten at Fujifilm and the new labeling process began.

Alberry said, “In truth the original idea for the new labels came from our partner company EFILM in Hollywood. I took their model and showed it to Marc who in turn came up with a prototype for us here in Australia. There are bespoke areas for information on each label that includes the Deluxe and DDP logos as well as all the relevant production information. Each label is easily customisable and the process is almost completely automated saving us time and money.”

The new Fujifilm LTO cine labels are created as a PDF which Alberry and his team link to their database and fill out via Adobe Acrobat. The labels are then printed out in pre-cut sticker sheets to match a required production template.

Alberry concluded, “Before we had the new labels each LTO label would take about five minutes. Multiply that by thousands of tapes and that’s a lot of time spent on labelling. Now with the new system we label in a fraction of the time, much more efficient and a better product for our clients. It’s a very intuitive process preferred by our producers like because all the information they require is so clear and accessible. I would prefer that our talented onset dailies crew focus on the creative content, securing the original camera neg and deliverables rather than worrying about labeling. This new labelling process has been a major help to make our workflow more efficient.”

A few manufacturers offer similar labelling services, Sony use a barcode system. But we kind of like the simplicity of a customised PDF that is printed on to sticky labels, particularly if you need to give LTO archives to a clients.

We’ve asked Fujifilm if its new LTO cine labels are a separate service or are attached as a customisable PDF file in each new LTO tape. We’ll update this article once we now.

**UPDATE**

We heard back from Fujifilm who has said that it supplies an A4 self adhesive sheet that has been die cut with all the options you need for the label and the box eg. spine, face of tape or box. Fujifilm also provides a USB with Adobe software within which you can alter any field eg. reel number and barcode, thus making the labels and box fully customisable.

This is great news for those of us charged with creating the labels!

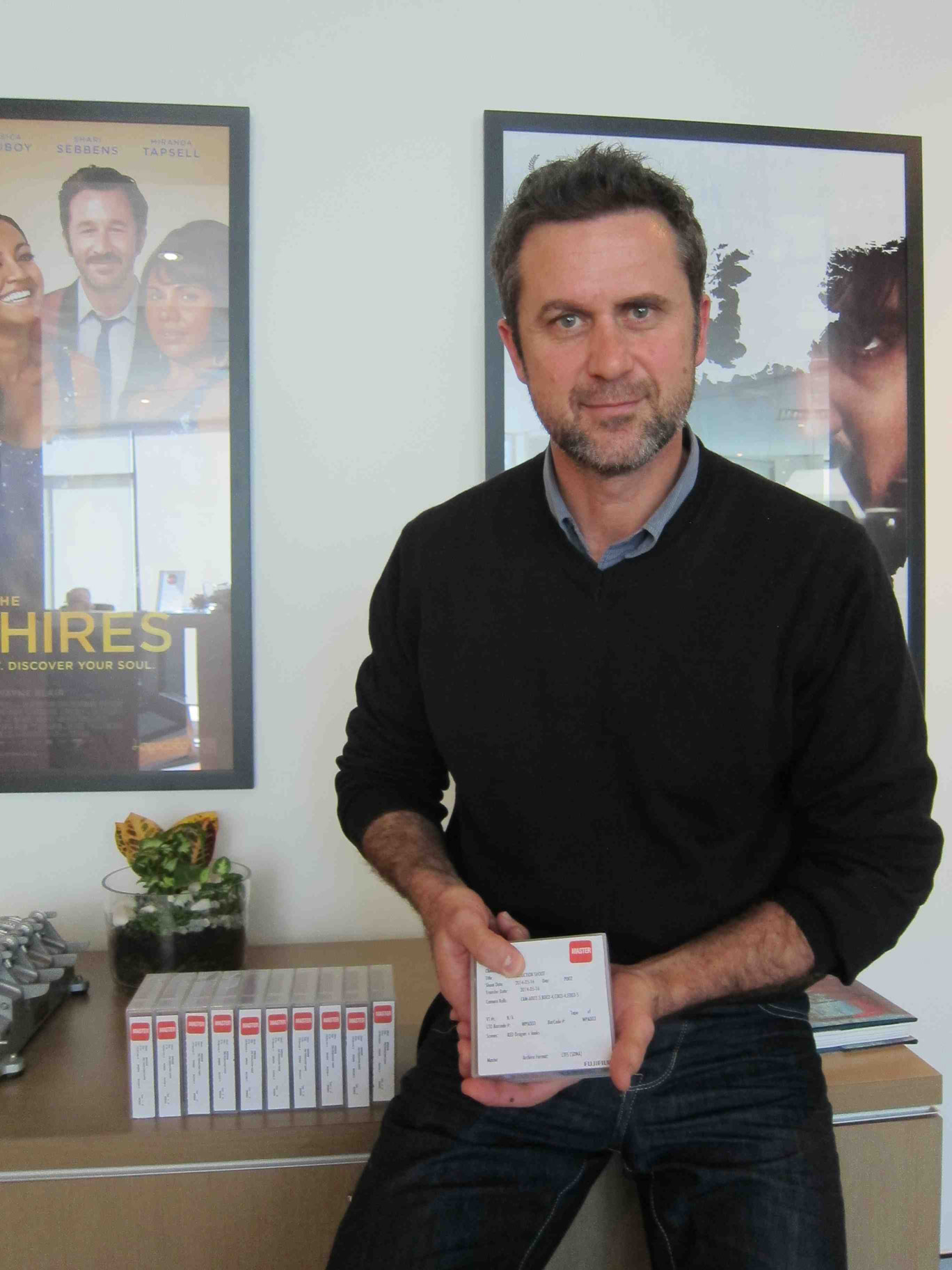

DDP Studios Technical Innovation Manager, Simon Alberry with Fujifilm’s new LTO cine labels

Excerpts from PR